Improvements of thermal insulations by latent heat storage

Extended standby periods of superinsulated devices can be achieved not only from improvement of the proper superinsulation (mostly by variations of its materials composition) but also from a combination with latent heat storage. Cool-down time of low, medium of high temperature storage units, or of pipings in case of a production break-down, can considerably be extended by this means. The method is not restricted to superinsulations.

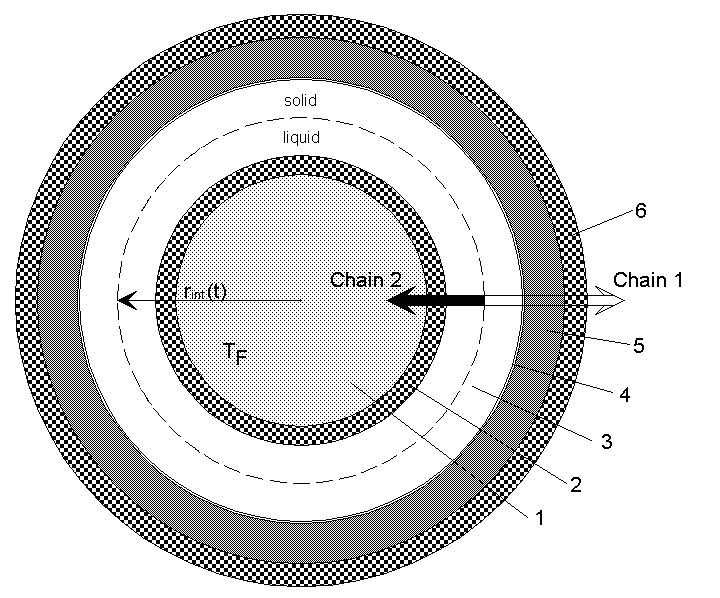

Layers of latent heat storage material are integrated between inner tube and thermal insulation, as shown in the Figure below, a cross section (schematic) of a superinsulated pipe furnished with latent heat storage material. The latent heat storage material is located between the inner steel tube (2) and a separator (4) that in case of a superinsulation (5) must be vacuum-tight. It is assumed fluid temperature, TF, exceeds melting temperature, Tm, of the phase change material and ambient temperature, Ta; accordingly, it is assumed the phase change material during normal operation of the pipe is in liquid state. Phase change of the storage material, between liquid and solid states, during cool-down of the fluid occurs at the position rint(t) of the cross section, i. e. at a definite radius, under ideal conditions. Since the temperature profile across the pipe changes with time, t, the position of the liquid/solid interface (dashed curve in Fig. 1) changes accordingly, from the outer surface of the inner tube to the inner surface of the separator. These positions denote fully charged or fully discharged states of the storage material, respectively.

In case of a "normal" (non-evacuated) insulation, the position of the phase change material in the cross section of the pipe, with respect to position of the thermal insulation depends on the specific problem (quality of the insulation, temperatures): Instead of being surrounded by the thermal insulation, instead the phase change material could surround the insulation in this case. Which of the two options shall or can be realized has to be concluded from thorough thermal analysis, e. g. based on thermal network calculations of heat losses and temperature excursions (clearly, if superinsulation is used, the phase change material will be surrounded by the insulation). Note that heat transfer in phase change materials may be complicated by inhomogenous solidification and hysteresis after numerous cycles.

Details how to calculate transient heat transfer can be requested from the author or can be found in the forthcoming edition of the VDI Heat Atlas, Section K6, Superinsulations (to appear in 2010).